In House R & D

Product Development Capabilities :

To Carry out such product Development, the Design skills used:

Basic Skill sets :

- Digital Electronics Circuit design.

- Analog Electronics Circuit design.

- Microprocessor based hardware design.

- Power Electronics system and control design. (Involving thyristors & IGBTs)

- Micro-Controller firmware using C compilers and Assembly language.

- Digital Signal Processors instrumentation design (firmware & hardware)

System Engineering Skill sets:

- Concepts of electrical parameter measurement, analysis and PF control.

- Concept of Electrical Power Quality Mitigation by passive and active controls.

- Concepts of variable speed AC and DC drives.

- Concepts of Data Logging and Analysis.

- Data Communication using Hand held unit, GSM/GPRS, RF (UHF), MOD-Bus, USB, Bluetoth, Wi-Fi, TCP-IP.

- Automation system designing and software.

- Concepts of Switch Mode Power Supplies with regulated voltage and current sourcing.

- Protection to the electronics under EMI/EMC.

In-House Designing Tools:

Software Tools:

- Texas DSP TMS 320 series compiler.

- ARM Cortex M3, M4 KeilCompilers for 32-bit microcontrollers.

- C++ compiler Keilfor Silicon Labs series microcontrollers.

- Compiler for Atmel AT90S and ARM series microcontrollers.

- Simulator tool for Silicon Labs microcontrollers.

- AltiumPCB design and Circuit simulation package.

- Mechanical 3 D imaging Software Package.

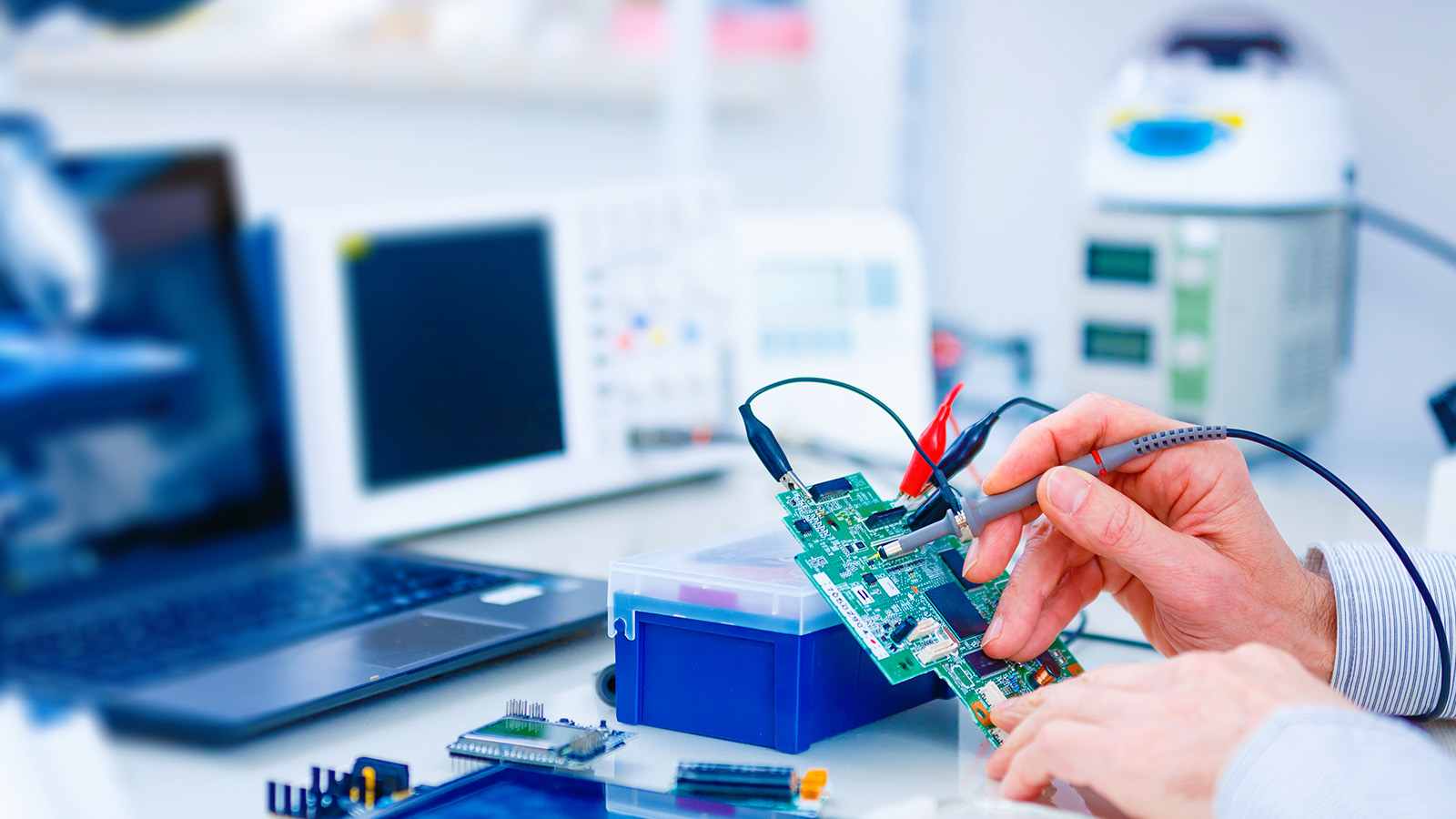

Hardware Testing:

- Calmet C300 Three phase Voltage and Current Source and Calibrator 0.02% accuracy.

- Single phase and Three phase sine wave generator for Voltage and Current. 2 nos.

- Digital Storage Oscilloscopes High end models Tektronics. 2nos.

- 200Amp. AC, loading current source for heat run testing of thyristor switches.

- High temperature burn-In Chamber.

- General Testing equipment like 0.2class meters, Digital Storage Oscilloscope.

- High voltage and insulation testing equipment.

Support Type Testing Facilities:

The designing facilities available and used by us for various type testing:

These facilities are available with Govt. approved laboratories and are available for testing on chargeable basis.

- EMI / EMC testing facilities for electronic equipment.

- ROHS Compliance of the product developed.

- Mechanical vibration testing facilities.

- Temperature shock testing (-10C to +75C).

- Environmental testing (Humidity and dust).

- Calibration of the Power measuring equipment for 0.2 and 0.5 class accuracy.

- Other mechanical tests like drop test, seismic test etc.

- Certifying of the equipment as per IS, IEC or other internationally accepted standards.

E.T.D.C., Pune and E.R.T.L.Mumbai:

- Power measurement and calibration.

- EMI / EMC testing.

- Harmonics measurement testing

I.D.E.M.I., Mumbai; E.R.T.L., Mumbai and N.E.C.Nashik

- Mechanical vibration test.

- Environment testing.

- Temperature shock testing.

C.P.R.I., Bangalore and E.R.D.A.Vadodara

- Output short circuit testing.

- 50kA fault simulation.

×

![Popup Image]()